In 1960, Cambridge University graduate, Tim Eiloart, set up a small technical consultancy business called Cambridge Consultants and invited his friend and fellow graduate, David Southward, to join him. It was the start of a fascinating career for David who, for the next 40 years, worked and ran many of the UK’s most influential technology companies. David tells the story of Cambridge Consultants and its associate companies, describes his later roles at Sinclair Radionics and Sinclair Research, and reveals some of the ups and downs he experienced working on innovative and cutting-edge technology projects.

A view of Enderby’s Mill in St Ives, Cambridgeshire. Once the home to Cambridge Consultants and Sinclair Radionics. David founded the former company and worked for the latter. The original mill building is the tall one on the right

“Everybody sort of assumed that computers were going to sell and sell and sell,” says David Southward, recalling the situation which led to the demise of Sinclair Research, “so all the companies and retailers were ordering them, and then everybody found that they had oversold! There wasn’t the market there so the shops wanted to give them back and that caused cash flow problems.”

Those cash flow problems eventually forced Clive Sinclair to sell his business to competing entrepreneur Alan Sugar, and soon afterwards many people who had been instrumental in the UK’s technology boom of the early 1980s were looking for new employment opportunities.

David Southward was one of those temporarily out of a job, but it was not the first time he had experienced the slump of a business which relied on venture capital and large sales to survive.

A Scientific Mind

At university David studied natural sciences rather than engineering, yet a passion for building things, coupled with a stint making tools during his National Service, conspired to set him on a different career path.

“I always made things at school,” he recalls. “I went through a phase of making aeroplanes – radio control ones, including the control. I also built radios and hi-fis and I even made a car shortly after school. It was one of these things with a space frame chassis. It had a Ford Consul engine, an MG Gearbox, a Woolsey rear axel and a fibreglass body, the last of which I bought for about £80 and fitted. It actually looked quite smart.

“I collected the bits over time. I bought a Ford 8 van initially as a source of parts; for its steering and the front axels, but subsequently fitted the rack and pinion steering from a Citroën Light 15 which I found in a scrap yard in Sweden. The car had a little bit of absolutely everything under the sun. I still had it when we first started Cambridge Consultants, and somebody remarked that it would go backwards almost as fast as it would go forwards!

“Although that was a long time ago, the car is still going strong. The space frame chassis was made by somebody called Butler and the son of the Butler family that made the thing subsequently bought the car and run it to this day. And a short while ago he invited me to a meeting where this car was actually the star of the show, which was rather surprising!

“I also made a 14-foot speed boat on the top floor of the London house my parents lived in. The most extraordinary thing about it was trying to get it out because it was made in a spare bedroom on the sixth floor, right at the very top of the house. I worked out that it would just go out if I took all the doors out upstairs. It did and I managed to get it out onto the flat roof. I wrapped it in carpets and then lowered it right the way down. My father was a doctor so it went in through various consulting rooms at the bottom of the house, then out through the front door. It was a work of art getting it out.”

The ‘flat’ screen TV, which David worked on for Clive Sinclair

Supply or Service

After school David secured a place at Cambridge University to study natural sciences, however, at that time all young British men were unavoidably obliged to do a spell of National Service, either in the forces or a public service role of some prescription. David chose to do his Service before university, rather than after, and opted for a Ministry of Supply scheme.

“That is where I met Tim Eiloart who a lot of people will probably already have heard of,” explains David. “He was the actual founder of Cambridge Consultants. He and I met at this Ministry of Supply scheme where we were apprentices making a set of tools and learning how to use lathes, milling machines and things like that. The deal was that if you were successful they paid for your education. We did a year at the Woolwich Royal Arsenal factory, and then we both went on to Cambridge to study chemical engineering, although we still had to go back to the factories to work during the holidays.

“They were called the Royal Ordinance factories and were where they made TNT and all the ingredients that went into it. For example, they made all the acids; like concentrated nitric and concentrated sulphuric acid, so there was quite a lot of chemical engineering at the plant. And the factories were completely self-contained so if there was a war they had their own electricity supplies and everything.

“National Service was just about to end at that time, I think, so both of us just caught it, but we entered into the scheme with about 700 other people. Tim actually came top in this Civil Service exam and I think I was about fourth. It was very good training although it was incredibly boring for the first year, because we had to file our own set of tools. At least you learnt about how to use them properly! It was during that time that I was working on the car and the speed boat.

“Although Tim and I went to university at the same time he took a year out to go on a balloon trip from the Canaries, over the Atlantic to the West Indies. It was a project called the Small World and it was very celebrated in all the papers at the time. There were four of them: Tim and his father, Bushy, and two other chaps.

“So our ways split and I finished a year ahead of him. I then went into the city for a year, nominally at the behest of my father who thought that I should know something about accountancy! So I studied accountancy for that year after my four at Cambridge, but that absolutely wasn’t for me!

“Having done a little bit of accountancy so that I knew how to write books up and such things, I was casting around for a serious job, and Tim Eiloart, who was working at the experimental psychology laboratory in Cambridge by that time, said ‘Why not come up here? I can give you a job.’ So I came up to Cambridge, stayed with him, and worked for about a week at the job that he had offered me in the psychology laboratory, which turned out to be a non-job because, although I’d got a formal letter of appointment detailing holidays and all the rest of it, it hadn’t been agreed by his head of department. Tim was a pretty lowly creature and no way was he allowed to offer anybody a job. So that came to a halt pretty quickly!

“But that’s was when it transpired that there was actually quite a lot of work that the psychology laboratory, in particular, was putting out for local instrument makers, and, although we hadn’t any tools or machinery, we thought, ‘Why not give it a go?’”

69 Histon Road, Cambridge, where Cambridge Consultants had their first base

Cambridge Consultants

Tim had already registered Cambridge Consultants by the time he and David decided to work together, although at that stage the company didn’t employ anybody full-time. The initial idea was to provide a technical consultancy service which sourced the expertise for a range of specialist jobs, but the plan soon changed, as David explains.

“The whole concept of Cambridge Consultants was that it could find a technical specialist for any particular scientific field and put them in touch with industry. For example, supposing somebody was studying cheese and wanted to read a Polish paper about cheese making. They would have to find a specialist who knew all the technical jargon involved in cheese making and who also knew Polish. It turned out to be quite a difficult thing to do and it wasn’t a very satisfactory method of getting a company off the ground, really, and what we soon found was that we were actually doing the work ourselves.

“So what we did then, with a little bit of cash from both our parents, was set up a workshop at 69 Histon Road, at the back of a company called Polyhedron Printers, which was owned by a friend called Rodney Dale. We took on work making prototypes for the psychology laboratory and a lot of local industry; including commissions from parts of the Pye Group. Cambridge Prototypes is the name we traded under initially but that was under the wing of Cambridge Consultants.

“We had a little lathe and milling machine and hired a couple of really good instrument makers. In those days, Cambridge Instrument Company, who were famous for making the electron beam microscope, used to train instrument makers and ran a very good apprenticeship scheme, which, of course, nobody these days does. So we had a pool of labour in Cambridge that was extremely skilled and there were a lot of scientific instruments being made.

“At that stage Cambridge Consultants had one secretary on the top floor of 8 Jesus Lane in the centre of Cambridge and I had the workshop at Cambridge Prototypes. Then after about a year we started trading under Cambridge Consultants, Tim left the psychology laboratory and we expanded the premises at 69 Histon Road. It was about 1960 when I started, so that would have been 1961, I suppose.”

The work given to Cambridge Prototypes turned out to be varied, interesting and challenging. The company were called upon to make all sorts of esoteric pieces of equipment, often to help the university departments carry out very specific experimental research.

“It sounds a bit silly,” continues David, “but one of the biggest jobs we handled right at the beginning was making a piece of equipment to find out the characteristics of insect muscles – specifically bees. It was a vibrator to which you attached to the insect’s muscle and it vibrated it over a very accurate and precise distance at a set frequency. You then looked at the other end of the muscle to see the force that was generated.

This was done for a professor of zoology in Oxford, but what made it a bit difficult was that he wanted to measure it, not only in the normal atmosphere, but also in various other atmospheres; up to quite high pressures of about 1000PSI.

“The base plate for this thing was about two inches thick, 14 inches across and was made of stainless steel. This was because the vibration levels involved were extremely low and we didn’t want it to pick up the rumble from a passing truck, for example. It was a really solid piece of engineering and everything was stainless because it had to work in these varying atmospheres.

“We couldn’t make the pressure vessel itself so that was sub-contracted to another company. That looked almost like an oxygen cylinder with the top cut off, except it was larger in diameter.

“At that time we didn’t have any electronics expertise, so we used a friend of ours who was doing his PHD at the engineering labs. This was before transistors were in use so everything had to be done with valves and it was a hell of a beast. I can’t remember how much we were paid for it but probably about £3000.

“That was one of the most ambitious things that we tackled back then. But there were all kinds of instruments that people wanted. For example, we made a wind tunnel for aphids! Aphids are steered by, or attracted to, various frequencies of light, so the idea was that you would shine polarised light of various frequencies on a pseudo sky – which was just a bit of cloth through which the air passed – and watch how the aphids took off.

“I can’t remember too much about it but I just know that it was a thing of about a metre square in cross section. The airflow involved was very low but it had to be variable because you had to find out how hard the aphids were striving to get to the light that you were shining on the sky.

“Shortly after setting up with not much electronics expertise, we had some engineers join us. One was a chap called Peter Reiner, the other was Gordon Edge, and we made things like electronic petrol pumps for a garage forecourts, at a time when people hadn’t got such things. You could put a pound in and you got a pounds worth of petrol out. We made those for Gilbarco, which is one of the petrol manufacturers. And we did a similar thing for a private individual who wanted to get an idea off of the ground.

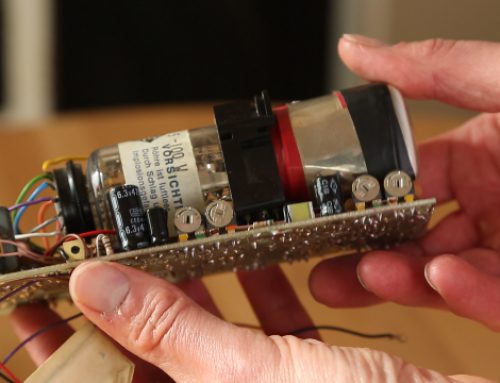

“One of the typical things that we made, for example, was a TV audience measuring instruments for AGB. They were a big market research organisation – the sort of people who would tell you that 9 million people were watching East Enders, etcetera, etcetera.

“I can’t remember exactly how it worked but every time you changed the channel it could tell what you were watching so AGB installed these instruments in thousands of homes throughout the country and from that they could work out what the audience figures were likely to be.”

8 Jesus Lane, Cambridge. “At that stage Cambridge Consultants had one secretary on the top floor of 8 Jesus Lane in the centre of Cambridge.”

The Next Step

Tim and David were, by this stage, fully involved in the making of electro-mechanical instruments of one sort or another and, as it turned out, neither one would ever put their chemical engineering skills to any practical use for the benefit of Cambridge Consultants. Despite not making a great deal of money, they expanded the company rapidly so that it could tackle the diverse range of bespoke designs it was asked to complete, often deciding to create a new company trading within the Cambridge Consultants group to tackle the new line of work.

David admits that their motivation for expansion was at least partly fuelled by a desire to find that elusive big money-making venture.

“Making prototypes of various instruments is extremely difficult,” he explains, “because things always take longer and cost more. It was always next year that we were going to make a profit and we were always trying to be ‘cost plus’, but the client would always say, ‘No, I’ve got a finite amount of money, so I want a fixed price,’ as it were.

“When you are making prototypes of one thing or another there are always things you find out the hard way – a bit by trial and error – whereas if you are doing the same thing again and again it really is much easier. It was always a hassle and we didn’t actually make much money. We thought that what we needed were bread-and-butter products and were always looking for something to make our fortune.

“At the time we were also quite friendly with Clive Sinclair and could see that he was selling enormous numbers of things like that. Clive had bought some transistors and was looking for somebody to grade them into red spot and green spot transistors, which was into high gain and low gain. We had an engineer we weren’t entirely happy with, so he had a little room at the end of 69 Histon Road for a short spell where he was working for Clive.

“So it was always at the back of our minds that we’d expand and eventually, in 1968, we moved from Histon Road to quite a big building in Bar Hill. The premises were on the site that is now occupied Tesco. It was where I think the petrol pump station is now.”

“In the mean time we started expanding like anything and there were quite a lot of different companies within our umbrella. Gordon Edge was extremely good at electronics so we’d set up a company called AIM Electronics and even turned Cambridge Consultants into AIM Associates and made Cambridge Consultants one of a number of trading companies within the group. Another one of them was Cambridge Audio, which made hi-fi.

“Soon there was AIM Electronics, AIM Buyer Sciences and AIM Physical Sciences, the last of which made polarisers and other things. Once we had a manufacturing requirement, which was some time around 1969, we took over the Enderby’s Mill site at St Ives, and then all the manufacturing side of things happened at the mill.

“We rented the whole site which included the buildings, some sheds there that we filled with machine tools and the mill house itself. We also did a deal with Tim’s father, Bushy, who took over all the buildings on the river side and converted them, one-by-one, into flats. I can’t quite remember what the details were but originally we took over the whole site and split that fairly rapidly into the bits. The area adjacent to the bridge into St Ives was the bit Tim’s father looked after.

“We also had a long shed we called Dirkcam, which was where we were building an experimental weaving loom that I was involved with. It was to manufacture a patterned carpet at high speed, so that was put in there.” TF

Part 2 of our interview with David can be found here: Part 2